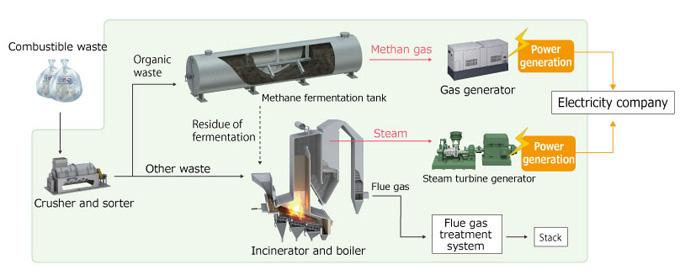

Combined system of methane fermentation and stoker-type incinerator enables maximum utilization of the energy in waste.

Biogas recovery plants are facilities that produce biogas power from methane fermentation of organic wastes such as kitchen waste, moist paper etc.

By generating power from renewable energy, we can both reduce the impact on the environment and achieve high efficiency energy recovery.

TAKUMA has been actively developing a combined system that integrates a biogas recovery plant with a stoker-type incinerator.

By adopting this system, it is possible to have two types of power generation: steam turbine power generation, using steam from the waste heat boiler; biogas power generation, using the methane gas that is produced. Compared to waste treatment by only a stoker-type incinerator, this system allows more high-efficiency energy recovery. Treating waste suitable for incineration in a stoker-type incinerator and waste suitable for methane fermentation in a biogas recovery plant, it is possible to maximize the extraction and utilization of the energy in waste

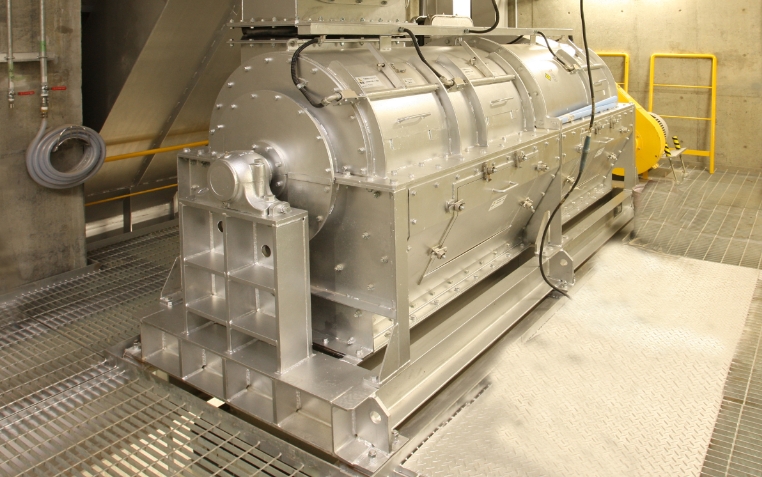

TAKUMA's biogas recovery plants use a high-temperature dry methane fermentation system. This system has a broad treatment scope that lets it generate methane from vegetation, paper, and other waste as well as from garbage.

Waste sent to the methane fermentation tank is sorted by a crusher and sorter. Since this system can automatically separate garbage, vegetation, and paper in collected waste from other types of waste that are not suitable for methane fermentation, there is no need to make changes to existing waste collection programs.

The gas-fired generating system generates electricity using biogas created by the methane fermentation tank in a highly efficient manner.

Sorting residue left over from the crusher and sorter and fermentation residue emitted by the methane fermentation tank are characterized by higher heat values and more uniform properties than unprocessed collected waste. A high heat recovery rate can be achieved by means of mixed combustion in a stoker-type incinerator.

In 2013, TAKUMA was the first company in Japan to deliver a combined system that integrates a biogas recovery plant with a stoker-type incinerator to a municipality. It is now possible to have high-efficiency power generation and energy recovery with even small-scale facilities which have difficulty producing power.

In addition, TAKUMA received a new order in 2016 from Miyazu Yoza Union Environment for a DBO project for the construction and operation (approx. 20 years) of a combined system.

| Facility name | Nantan Clean Center |

|---|---|

| Purchaser | Nantan Regional Administrative Association |

| Completed | August 2013 |

| Treatment Capacity | Stoker-type incinerator:43 tons per 24 hours × 1 unit Biogas recovery plant:24 tons per 24 hours × 1 unit |

| Facility name | Miyazu Yoza Clean Center |

|---|---|

| Purchaser | Miyazu Yoza Union Environment |

| Completed | June 2020 |

| Operation period | approx. 20 years |

| Treatment Capacity | Stoker-type incinerator:30 tons per 24 hours × 1 unit Biogas recovery plant:20.6 tons per 24 hours × 1 unit |

After-sales Services