Earning customers’ trust by manufacturing products based on extensive experience, advanced technology

The Harima Factory began operating in 1942 as our boiler manufacturing base. The facility, a pioneer in the boiler industry, has manufactured more than 3,200 boilers for an array of applications, including industrial, energy, and marine installations, and delivered them to customers in Japan, Southeast Asia, South Korea, China, Europe, and Africa. The facility continues today to harness TAKUMA’s extensive experience and advanced fabrication technologies to manufacture flagship offerings--boilers, stokers, and pressure vessels--with heartfelt dedication to producing reliable products.

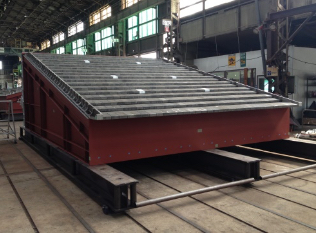

Our new factory, which was completed in January 2023, features production structures that let it satisfy an increasingly diverse range of customer needs, for example for larger boilers and higher temperatures and pressures. Moreover, a focus on deploying the latest equipment and streamlining work has fueled productivity improvements while ensuring the skills of master craftsmen can be passed on to a new generation at a sustainable production facility that’s both people- and environment-friendly. Going forward, the factory will continue to contribute to customers and society by producing high-quality products.

Our Harima Factory produces boilers, stokers, and pressure vessels, all of which are core components of Takuma plants.

Boilers are designed one at a time to meet the needs of customers’ applications and then manufactured by craftsmen. Our new factory delivers improved productivity thanks to an equipment layout designed to accommodate production processes and production control tools that make it possible to quickly share information while streamlining work and reducing labor requirements.

We use digital tools to record and analyze work performed by experienced, high-value-added technicians and use the resulting data to improve our craftsmen’s skills. In this way, the skills of master craftsmen can be passed on, allowing us to continue to realize high-quality manufacturing.

In addition to preparing to recover quickly in the event of a natural disaster so that we can continue business operations, we’ve secured an emergency power supply, stored supplies, taken steps to prevent flooding, and improved seismic resistance so that the factory can be used as a shelter. In addition, energy savings have improved the facility’s environmental performance, and its use of 100% substantially renewable energy reduces greenhouse gas emissions.

To ensure plants delivered by Takuma can be used in a stable manner over the long term, our Supply Lab is developing after-sales service structures with extensive features in the twin areas of operations and maintenance, example by keeping special parts with long lead times on hand in our new warehouse, using ICT to make possible central management of information about part inventories at facilities we operate, and working closely with Takuma’s Solution Lab.

O&M, Operation Management, and Maintenance

| History | 1942 The Harima Factory starts operations. 1985 Heat exchanger manufacturing facility completed. 1988 Vacuum equipment manufacturing facility completed. 1995 Central Laboratories completed. 2013 Solar power plant completed. 2023 Harima Factory renewal construction completed Opened "Supply Lab," after-sales service facility |

|---|---|

| Area | 137,995m2(site) 28,109m2(buildings) |

| Permits and certifications | Manufacture of thermal equipment for power generation (Ministry of Economy, Trade and Industry), Permission to manufacture boilers and pressure vessels (Ministry of Health, Labour and Welfare), Permission to manufacture cranes (Ministry of Health, Labour and Welfare), Manufacture of specific high-pressure gas facilities (Ministry of Economy, Trade and Industry), ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System), Type I Process Certification (Thermal Power Generation) (Private Sector Product Certification, Electricity Business Act) |

1-2-1 Shinhama, Arai-cho, Takasago, Hyogo 676-0008, Japan