We turn waste into resources and reduce final disposal volume.

Gasification melting furnaces subject waste to thermal decomposition and gasification followed by combustion while melting the ash that remains. Ash melting furnaces melt ash generated by incinerators. Both comprise technologies for melting the ash in waste and turning it into slag. Since the recovered slag can be reused in the manufacture of concrete aggregate and asphalt paving, the underlying technology yields significant reductions in the volume of waste slated for final disposal.

TAKUMA meets a variety of customer needs with its three technologies in this area: kiln-type gasification melting furnaces, plasma-type ash melting furnaces, and surface-type ash melting furnaces.

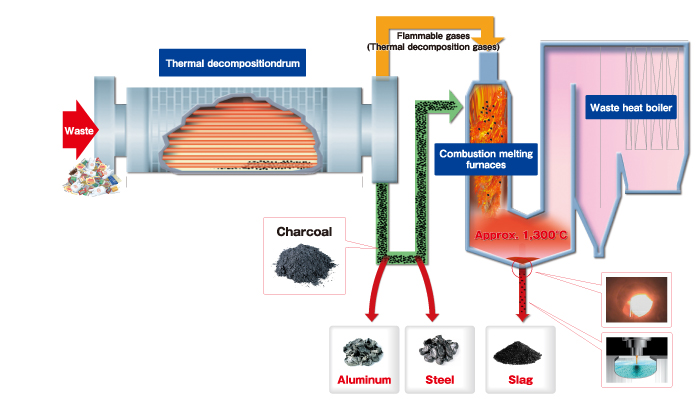

Kiln-type gasification melting furnaces comprise a treatment system with extremely high environmental performance since they can not only recover resources such as aluminum, steel and slag from waste, but also generate electricity using the surplus heat.

This system uses a thermal decomposition drum to break down the waste stream into thermal decomposition gases and charcoal. After aluminum and steel have been recovered from the charcoal, the thermal decomposition gases and charcoal are burned at high temperature and turned into slag in a combustion melting furnace. Heat is recovered from the combustion gases that are generated by the combustion melting furnace using a waste heat boiler and used to generate electricity.

Waste is broken down into flammables gases and charcoal.

Recyclable materials are recovered from the charcoal.

Flammable gases and charcoal are melted at the high temperature of approx. 1,300°C, and slag is recovered.

The slag can be used as road paving material and for other purposes.

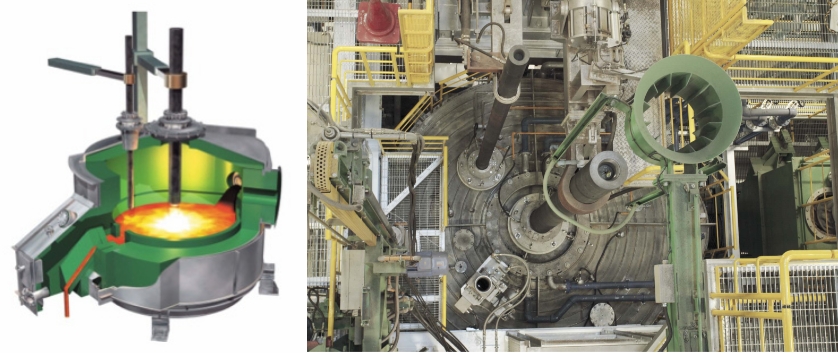

Plasma-type ash melting furnaces melt ash from an incinerator using a plasma arc (i.e., using thermal energy obtained from electricity). Since they use electricity, they are well suited to facilities with steam turbine generators.

Features

Surface-type ash melting furnaces melt ash from an incinerator by means of a burner (i.e., using heat from the combustion of fuel). Since they do not require electricity, they are well suited to use with small furnaces.

Features

After-sales Services