Working through initiatives to utilize digital technologies and promote open partnerships and innovation, the Takuma Group will look to further bolster its competitiveness by adapting to changes in the social environment, focusing on proposals based on customers’ needs, R&D to facilitate them, and technological improvements.

Progress in the Fourth Industrial Revolution and the development of information and communications technologies is rapidly transforming conventional products and services. Plant Engineering, Procurement, and Construction (EPC), operation management, and maintenance are no exception, and the transition to digital technologies will only accelerate going forward against the backdrop of trends including labor shortages. Takuma is pursuing development and other initiatives from a medium- and long-term perspective so that we can create added value, for example by realizing technologies facilitating remote operation of plants and realization of fully automated operations using AI, streamlining and reducing labor requirements for operations by utilizing data, and strengthening competitiveness in the areas of EPC and after-sales services.

Solution Lab, our remote monitoring/operation support center that utilizes the latest IoT solutions, provides 24-hour plant monitoring and operation support. We are also working to achieve stable plant operation by reducing manual operation of waste incinerators with the introduction of the ICS AI-based combustion control system as well as strengthening and utilizing the functions of POCSYS, a system that collects and analyzes operation data of each plant.

Development of AI-based automatic combustion stabilization technology

We developed a combustion Artificial Intelligence (AI) that can make judgments concerning incinerator operation on par with those of an experienced operator. By combining the AI with a conventional automatic combustion control system, we have reduced manual control inputs from incinerator operators by 99% while maintaining stable combustion.

Since our founding, we have been providing high-quality EPC and operation management and maintenance services based on our extensive experience and accumulated skills. In order to ensure that these experiences are passed on to the next generation, we are working to share knowledge and convert it into formal knowledge with digital technology. In this way, we aim to improve the capabilities of each individual and the quality of our services, as well as improve efficiency and reduce costs with the introduction of digital tools, and strengthen our competitiveness in EPC and after-sales services. As an example, we are promoting various initiatives, such as using 3D scanners to understand the latest conditions in plants and improve the accuracy of design and maintenance.

To ensure that we can consistently supply the products and services demanded by customers and society, we will accelerate R&D as well as efforts to strengthen our proposal capabilities through further deepening of partnerships with other companies and organizations.

We are promoting collaborations, alliances, and M&A with related companies in order to bolster functions such as strengthening the EPC business and recurring revenue model businesses and expanding the number of personnel.

Acquisition of Techno Links Inc.

We have acquired a 100% stake in Techno Links Inc., a manufacturer with operations spanning the design, fabrication, and installation of environmental recycling systems*, as well as associated after-sales service. By augmenting Takuma's overall plant design capabilities with this new subsidiary's ability to design custom equipment to suit the properties of specific waste streams, we will gain the ability to build more efficient sorting systems.

*Equipment that makes up recycling plants (equipment for crushing, sorting, compacting, and transporting drink containers; equipment for sorting and compacting other plastics; belt conveyors, etc.)

In an effort to strengthen our ability to produce proposals for solving issues facing customers and communities, we are pursuing collaboration with knowledgeable companies and organizations.

Initiatives at Imabari City Waste Management Center

Having adopted the concept of Phase Free*1 operations at waste treatment facilities, Takuma built and operates Imabari City Waste Management Center as a new type of waste treatment facility that contributes to its community during both normal times and times of emergency.

The plant has a role as a disaster-prevention base to safeguard residents in the event of an emergency as well as serving as a familiar presence to residents during normal times, other than incinerating waste. In addition to providing functionality to serve as a shelter where people can take refuge with peace of mind, the facility is improving its ability to deal with any contingencies that might arise in the event of a disaster and strengthening its cooperative structures by joining the city, a Special-Purpose Company (SPC)*2, and local NPOs as well as residents to hold annual training involving opening itself as a shelter and carrying out improvements based on that training. Moreover, the Center is earning praise not only for playing a role in times of emergency, but also for operating as a Phase Free facility that maintains a familiar presence for residents in regular times by allowing them to enjoy sports and events.

*1: A concept that augments daily operations with the ability to play a role in the event of a disaster.

*2: Imabari High Trust Co., Ltd., a Special-Purpose Company (SPC) established with investments by Takuma and Takuma Technos Co., Ltd., which is part of the Takuma Group, is tasked with operating Imabari City Waste Management Center.

Waste treatment facilities in service to the region both "normally" and "in emergencies"! In-depth analysis featuring "Imabari City Clean Center"

In addition to joint research with universities and other companies, we are working in partnership with other companies to develop new businesses and decarbonization technologies.

Participation in the C2X Project

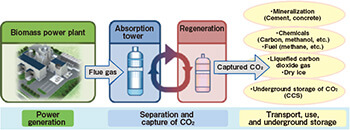

Takuma is participating in the Carbon to X (C2X) project, an open innovation business platform dedicated to helping realize a decarbonized society.

The organization emphasizes commercialization through inter-industry partnerships to promote adoption of technologies for decarbonization and Carbon dioxide Capture, Utilization and Storage (CCUS).

By commercializing CCUS technology through the C2X project, for example in businesses that use collected CO₂ as a raw material to produce fuel or chemical products, we will realize a global vision for a sustainable, safe, secure, and comfortable decarbonized society based on

cyclical resource flows through adoption of renewable energy. As a leading manufacturer of municipal solid waste treatment plants, Takuma will contribute to the realization of a decarbonized society by working with local governments and local stakeholders to develop and study next-generation waste

treatment plant in order to achieve carbon neutrality by 2050 through C2X.

As demands have grown in recent years for realizing a decarbonized society through carbon-neutral technology and better protecting the environment against the backdrop of the problem of climate change, we are focusing on R&D and technological improvement in order to develop the technologies and products that are required by society and customers.

Development of a CO2 supply system for SARA Inc.

We developed a system for supplying a large volume of CO2 in a safe, economical manner from combustion flue gas from a biomass power plant and delivered it to SARA Inc. By locating the biomass power plant that incorporates this system next to a greenhouse, we have realized a biomass tri-generation system that uses heat, electricity, and CO2 in vegetable cultivation.

Through this system, which combines the expertise of SARA Inc., an expert in vegetable cultivation, with Takuma's flue gas treatment technology, we are contributing to smart agriculture that utilizes the fertilizing effects of CO2 while realizing economic, carbon-negative* operation.

The system received the Japan Machinery Federation Chairman Prize at the Federation's 2020 Equipment and System Awards for Excellence in Energy Savings.

*The system absorbs more CO2 than it gives off(making it carbon-negative) as its CO2 source is combustion gases from wood biomass, which is carbon-neutral, and because it makes effective use of the CO2 in those gases.

Biomass Power Plant Construction / O&M Project in Kasaoka

Effective use of CO2 in combustion gas in agriculture

We have commercialized and delivered a CO2 supply system (t-CarVe®) that directly uses CO2 in the combustion gas generated in biomass power plants to grow crops and a trigeneration system that also supplies heat and electricity to greenhouses in addition to CO2. These systems are now in use. With the cooperation of Machida City and in collaboration with Aeon Agri Create Co., Ltd., we are currently conducting a demonstration project in which this technology is applied to combustion gases generated from the Machida City Bioenergy Center (municipal solid waste treatment facility) (combustion gas from incineration facilities and combustion gases from bio-gas engines at biogasification facilities) to evaluate the growth of crops (strawberries) in greenhouses and to evaluate the safety of harvested crops.

Technology for separating and capturing CO2(chemical absorption method)

Working with the National Institute of Advanced Industrial Science and Technology, we are conducting joint research to develop technology for separating and capturing CO2 using a chemical absorption method that utilizes non-water absorbent for use with CO2 in flue gases from biomass power plants and municipal solid waste treatment plants. Under the Research, Development and Demonstration Project of CCUS Technology, which Takuma is carrying out with Nippon Paper Industries Co., Ltd., under contract from the New Energy and Industrial Technology Development Organization (NEDO) and which is conceived to yield energy savings and downsizing of equipment, we will research the targeted technologies, and we will look to use the absorbent to treat plant flue gases in the future as we evaluate its performance and work to commercialize it.

Conversion of CO2 in flue gas into solid carbon

This technology manufactures solid carbon using CO2 captured from the flue gases from municipal solid waste treatment plants as the raw material and energy from the same plant. This solid carbon is expected to be used as a raw material in fine carbon and other chemical products. In FY2023, this technology was selected by the Ministry of the Environment for the Project to Promote the Construction of a Regional Circular and Ecological Sphere Concept with a Waste Treatment Facility as the Core, and a feasibility study was conducted for its commercialization. We are currently conducting R&D under the technical guidance of Shizuoka University.

Biomethanation, which also yields a substitute for natural gas

This technology generates high-concentration biomethane from biogas from the methane fermentation of garbage and other waste and CO2 contained in flue gases by adding hydrogen and relying on a microbial process to convert the mixture into methane. It is characterized by low facility energy consumption and high operational stability. The technology offers a high level of versatility since biomethane can be used as a fuel to generate electricity or as natural gas, and we are currently conducting joint research with Kyoto University, Hokkaido University, the National Institute for Environmental Studies, Toho Gas Co., Ltd., and Ebara Jitsugyo Co., Ltd.