We will help alleviate the global problem of climate change using the technology and expertise we have accumulated over more than 80 years.

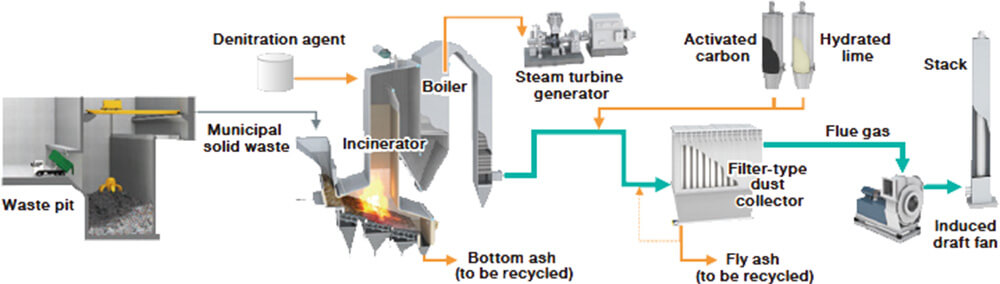

The municipal solid waste incineration plants and biomass power plants that we supply help save about 4.5 million tons of CO2 emissions every year by converting waste and biomass into energy.

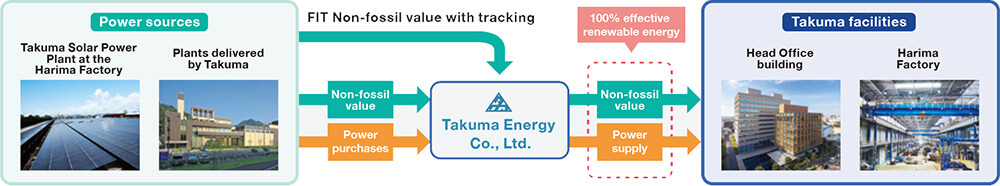

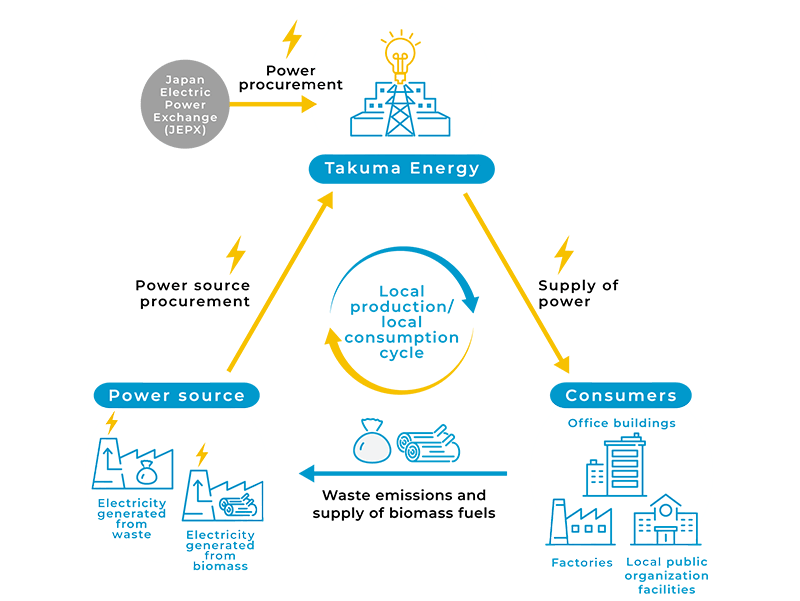

ESG DataOn April 1, 2022, Takuma’s Head Office building and Harima Factory began using power derived from 100% effectively renewable energy supplied by subsidiary Takuma Energy Co., Ltd. The power is generated by the Takuma Solar Power Plant at the Harima Factory in 2013 and by biomass power plants and waste treatment plants delivered by Takuma to date. This initiative has reduced annual CO2 emissions from Takuma’s Head Office and factory by about 1,616 tons of CO2 (FY2021 figures).

We’re working to reduce environmental impacts throughout the plant life cycle, including design, construction, operation, maintenance, and improvement, through initiatives to reduce fuel consumption and improve generating efficiency by boosting plant efficiency and to reduce CO2 emissions through energy savings.

Since delivering Japan’s first 24-hour operating waste incineration plant in 1963, Takuma has built and delivered more than 370 municipal solid waste treatment plants, the most of any manufacturer in Japan. Most of the treatment technologies used by plants are the result of in-house R&D by Takuma, which continues to embrace the highest standards of excellence while working to refine its technologies so that they can accommodate the needs of society it changes over time. Takuma contributes to resource conservation and environmental protection through a broad product line and after-sales service based on an extensive track record as the industry’s leading company.

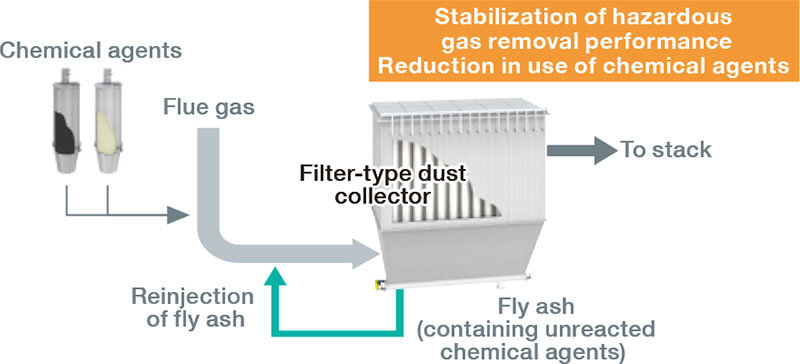

We contribute to the formation of a Sound Material-Cycle Society by working to improve incineration and flue gas treatment technology, promoting recycling of ash, and reducing use of chemical agents.

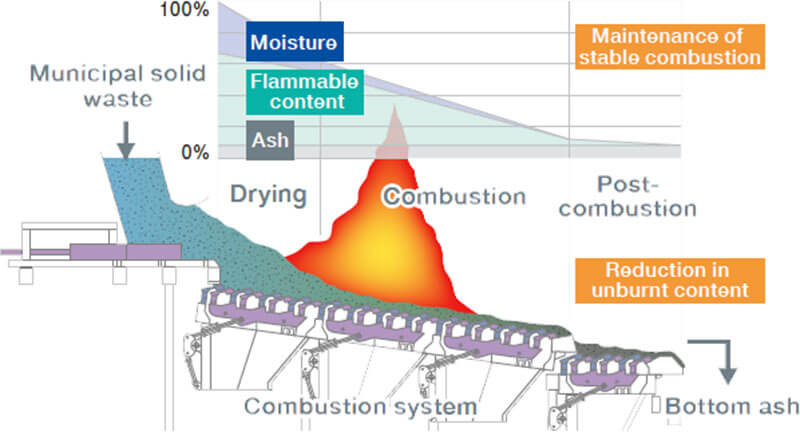

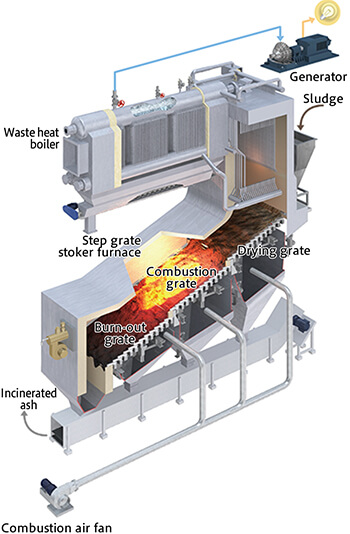

Takuma stokers incorporate enhancements and improvements that draw on our track record of deliveries, which makes us the No. 1 supplier of such systems in Japan, along with our treatment experience. We pursue ash recycling by maintaining stable combustion despite a diverse range of waste properties and creating bottom ash with few embers that exhibits uniform properties, making it well suited for use in cement recycling.

Fly ash collected by filter-type dust collectors contains chemical agents used to remove toxic chemicals (hydrated lime and activated carbon) that are still capable of removing toxic chemicals. This system consists of technology for utilizing such chemical agents to maximum effect by reducing chemical agent use and fly ash volume so that fly ash can be recycled efficiently and economically.

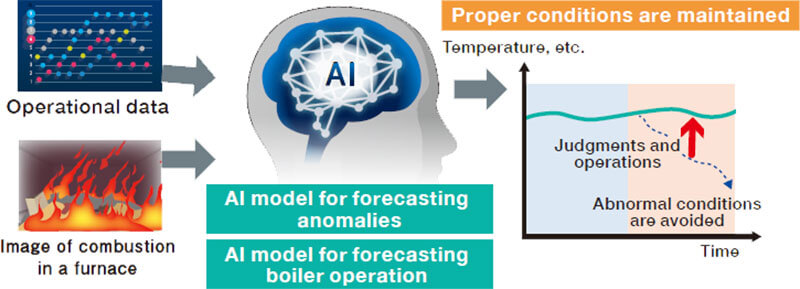

The introduction of AI-enabled combustion control and high-efficiency power generation serves to safeguard the environment in the surrounding area and reduce CO2 emissions.

This next-generation combustion control system, which uses AI technology, reproduces the operational skills of experienced operators. Since the system precisely forecasts combustion fluctuations that are unique to waste incineration to determine and implement the appropriate response, stable combustion conditions can be maintained at all times, even when the properties of the waste fluctuate over the medium and long-term.

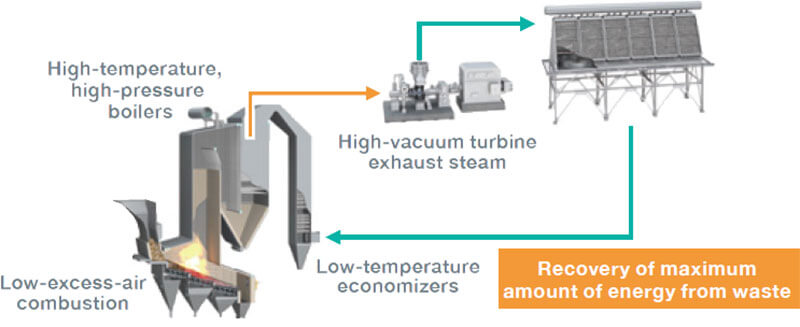

Municipal solid waste treatment plants demand high-efficiency power generation technology from the standpoint of reducing CO2 emissions. We help protect the Earth’s environment through such technology, including high-temperature, high-pressure boilers; low-excess-air combustion; low-temperature economizers; and use of high-vacuum turbine exhaust steam.

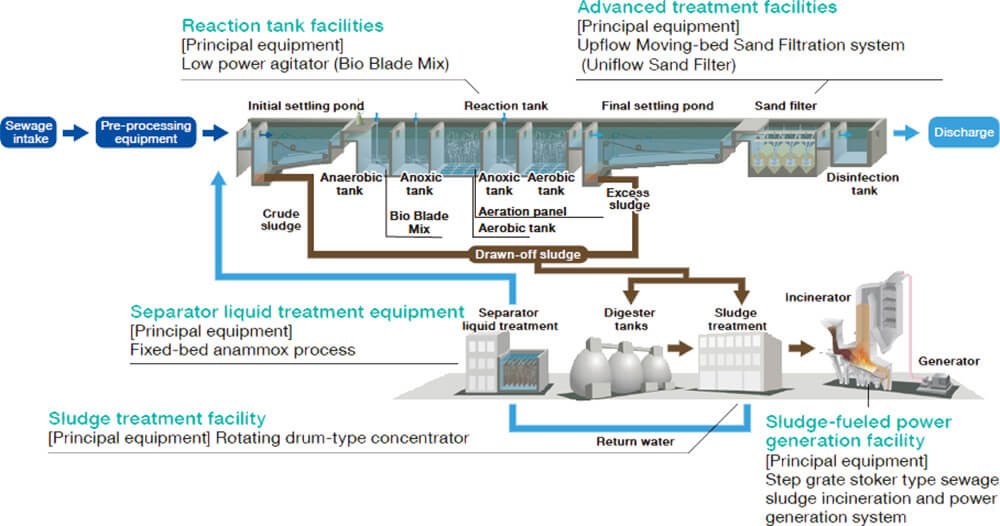

Since entering the water treatment business in 1962, Takuma has manufactured a variety of water treatment equipment over the course of more than 60 years while working to protect the water resources required by society and the greater water environment. In recent years, companies in this sector have been called upon to address social needs involving priorities such as energy conservation, energy creation, and Life Cycle Cost (LCC) reductions. In response, we have helped realize sustainable sewage systems by taking advantage of the reliable technology and extensive experience we have developed to date.

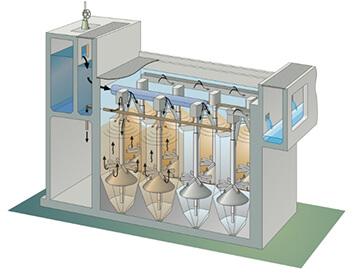

Our upflow moving-bed sand filtration system (Uniflow Sand Filter), which removes Suspended Solids (SS) from water, is primarily used for final treatment at sewage treatment plants to allow clean, treated water to be released into rivers. Some treated water is also reused at the facility, helping to conserve water resources. Uniflow Sand Filter systems boast top domestic market share in moving-bed sand filtration systems, and we have delivered more than 2,800 of these long-selling products, which feature water quality purification technology, in Japan. In recent years, many of the systems we have delivered have been a new high-speed model that delivers two to three times the treatment volume with the same area as conventional fixed-bed sand filtration systems. We are also seeing more projects that replace fixed-bed sand filtration systems with this system while retaining existing foundation work and related infrastructure.

Sludge generated by the sewage treatment process is a type of biomass, and such resources are expected to be used as renewable energy. Conventional sludge incinerators were net consumers of energy because they required auxiliary fuel and used large amounts of electricity, but this system draws on the core Takuma technologies of combustion technology and boiler technology to make possible an energy-creating system that generates more power than the incinerator consumes while using sludge as fuel, as long as it operates at or above a certain scale.

Takuma has helped resolve customer issues for many years by delivering numerous boilers and energy plants of various types and specifications as a pioneer of the boiler industry. In recent years, alleviating climate change and realizing a decarbonized society have been identified as issues that should be addressed on a society-wide level, and renewable energy in the form of solar, wind, geothermal, small- and medium-scale hydro, and biomass will play an important role in that effort.

Because trees absorb CO2 through photosynthesis during the growth process, wood biomass from forest thinning and other sources has the characteristic of being carbon neutral, in that use of energy from timber does not impact the atmospheric concentration of CO2. We will help resolve issues faced by customers and society by promoting renewable energy through utilization of wood biomass.

Advanced plant designs that can withstand stable operation over the long term are essential so that we can ensure customers can operate our energy plants with a sense of assurance. We design each plant after choosing the optimal combustion method based on customer requirements, the technology we have developed over our long history, and our extensive track record of delivered facilities. We also offer service (through maintenance and our O&M business) designed to ensure that plants can operate in a stable manner over the long term with security and reliability.

Since biomass fuels are not uniform in terms of their properties, such fuels are characterized by the difficulty of realizing stable combustion. We specialize in drawing on our extensive experience and advanced technology to utilize various types of biomass effectively by burning them in a stable manner. We continually strive to increase energy efficiency in our plant designs so that resources can be utilized to the greatest extent possible.

Since establishing Takuma Energy Co., Ltd., in 2015 to operate its Power Retail Business, the Takuma Group has worked to realize a regional Sound Material-Cycle Society through energy plants, for example by promoting the local production and consumption of power through an initiative in which Takuma Energy purchases power generated by Takuma-built plants and supplies it to regional public facilities and other consumers.

The Japan Society of Industrial Machinery Manufacturers has established a series of targets to be achieved by FY2030 based on the Japan Business Federation’s action plan. Takuma participates in the Committee on Environmental Equipment, of which we serve as the deputy chair, and in other committees. We provide our views on decarbonization in response to the Society’s initiatives, and we participate in decarbonization initiatives and climate change measures undertaken by the Society.

The Japan Environmental Facilities Manufacturers Association is an industry organization that works to realize decarbonization through waste and to build a Sound Material-Cycle Society founded on resource recycling and a Regional Circular and Ecological Sphere. Takuma participates by serving as a trustee and as a member (or chair) of various committees. By presenting and applying its views to the Japanese government and industry through various committees, the Association is working to realize decarbonization and to build a Sound Material-Cycle Society and a Regional Circular and Ecological Sphere.

We’ve participated in this organization, which emphasizes the commercialization of revolutionary technologies (decarbonization, CCUS, etc.) related to carbon-to-X (C2X) through inter-industry partnerships and collaboration among multiple companies with the goal of realizing carbon neutrality and a decarbonized society, from its founding.

We announced our support for the recommendations of the Task Force on Climate-Related Financial Disclosures (TCFD) in April 2022.

As the Group works to realize its corporate vision, we will strive to enhance initiatives that help realize a sustainable society by resolving issues faced by customers and society through the provision of products and services and by reducing our own CO2 emissions. In addition, we will work to enhance our approach to climate change and our information disclosure initiatives through dialog with stakeholders.

We’ve been a signatory to the United Nations Global Compact, which sets forth 10 fundamental principles in the four areas of human rights, labor, environment, and anti-corruption, since 2006, and we operate our business in accordance with our understanding of, and respect for, these shared global principles.

Our Harima Factory, which manufacturers boilers, a key piece of equipment at the plants we build, works continuously to reduce emissions and resource use by establishing targets based on environmental protection agreements with local governments and the ISO 14001 standard.

| Indicator | Target, Agreed value | FY2024 results | |||

|---|---|---|---|---|---|

| Indicator | NOx emissions (*1) | Target, Agreed value | 80.1 tons/year or less | FY2024 results | 0.460 tons |

| Indicator | Wastewater volume (*2) | Target, Agreed value | 123.5 m3/day | FY20234 results | Not to exceed target |

| Indicator | pH level | Target, Agreed value | 5.8 to 8.6 | FY2024 results | Not to exceed target |

| Indicator | BOD | Target, Agreed value | 14.0mg/l | FY2024 results | Not to exceed target |

| Indicator | COD | Target, Agreed value | 15.0mg/l | FY2024 results | Not to exceed target |

| Indicator | SS | Target, Agreed value | 8.7mg/l | FY2024 results | Not to exceed target |

| Indicator | T-N | Target, Agreed value | 18.8mg/l | FY2024 results | Not to exceed target |

| Indicator | T-P | Target, Agreed value | 2.3mg/l | FY2024 results | Not to exceed target |

| Indicator | Municipal solid waste emissions | Target, Agreed value | 20 tons/year (FY2024) | FY2024 results | 16.71 tons |

| Indicator | Industrial waste emissions | Target, Agreed value | 30 tons/year (FY2024) | FY2024 results | 20.50 tons |

| Indicator | Water resource inputs | Target, Agreed value | 65 L/hour or less (FY2024) | FY2024 results | 86.0 L/hour tons |

| Indicator | Power consumption | Target, Agreed value | 19 kWh/hour or less (FY2024) | FY2024 results | 19.6 kWh/hour |

*1 Value based on environmental protection agreements with Hyogo Prefecture and the City of Takasago.

*2 Value based on the Act on Special Measures concerning Conservation of the Environment of the Seto Inland Sea.

The Harima Factory has earned ISO 14001 certification, and it practices environmental management activities in accordance with an environmental management system that is designed to comply with international standards.

Our group companies Nippon Thermoener Co., Ltd.; Takuma Technos Co., Ltd.; Hokkaido Sanitary Maintenance Co., Ltd.; and Dan-Takuma Co.,Ltd., have also acquired ISO 14001 certification.