We provide solutions that extend throughout the plant life cycle, from construction (EPC) of municipal solid waste treatment plants for local governments to maintenance, primary equipment improvement and service life extension, operation management, and operation (O&M).

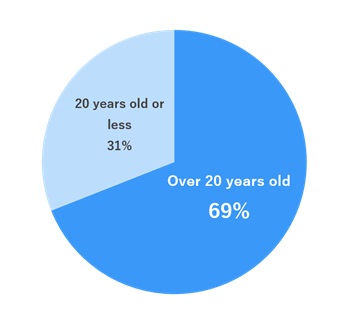

Some 1,000 facilities in Japan incinerate about 170,000 tons of waste per day, and those plants are aging, with about 70% of them having been operating for at least 20 years. With many facilities built during the 1990s to address the problem of dioxin emissions reaching the point in their service lives at which they need to be updated, we expect to see strong replacement and service life extension demand continue for the time being.

Prioritizing investment of management resources into receiving orders for municipal solid waste treatment plants (renewals and primary equipment improvement) and establishing a revenue model that maximizes the use of recurring revenue.

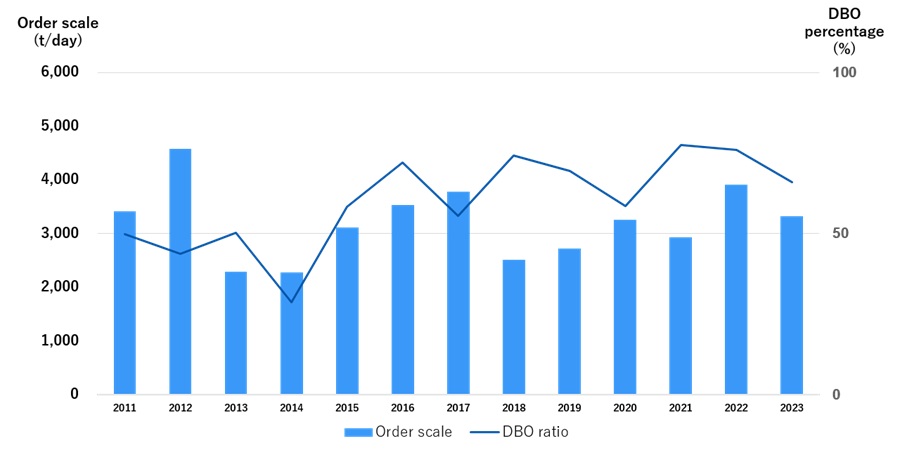

In the EPC Business, we aim to win at least three renewal orders per year on an ongoing basis and steadily meet the demand for service life extension by enhancing our proposal capabilities through differentiation in areas other than price based on our technological strengths and expanding our ability to respond to projects by increasing resources and improving operational efficiency.

In the Recurring revenue model businesses, through proposal-based sales, we will maintain and expand orders for after-sale services every year. In addition, we aim to achieve growth of recurring revenue model businesses by enhancing O&M proposals for non-contracted facilities and initiatives to reduce costs through data utilization.

In addition to construction (EPC) and maintenance of energy plants for private-sector operators, we offer operation (O&M) and other services.

We contribute to our customers‘ decarbonization through biomass power plants and large-scale plants that supply electricity and heat to their factories.

Demand for small- and medium-sized biomass power plants, mainly from domestic fuels (such as unused timber), continues, driven primarily by policies to promote renewable energy and decarbonization. In particular, we expect to see demand for renewal of existing plants (fuel conversion) in the paper and lumber industries and demand for new small- and medium-sized power plants (FIT/FIP, Non-FIT).

In the EPC Business, the aim is to continue winning orders, particularly for small- to medium-sized biomass power generation plants, including renewal of existing plants and proposals for new power plants. In after-sales service, we aim for recurring revenue model business growth by proposing solutions for energy savings, functional improvement, and service life extension, in addition to maintenance.

In addition to construction (EPC) and maintenance of water treatment and sludge incineration plants, particularly for sewage treatment plants run by local governments, we supply operation management and other services.

Contribute to the effective use of energy and decarbonization of sewage treatment facilities through greenhouse gas-reducing and highly energy-saving products.

In addition to renewal and service life improvement demand due to aging sewage treatment plants, demand for reduction of greenhouse gas emissions and effective utilization of biomass sewage sludge is growing in the sewage treatment field. Our step grate stoker type sewage sludge incineration and power generation system received two awards in FY2022 for CO2 reduction, energy saving, and energy creation.

Focus on securing ongoing orders with mainstay products (step grate stoker type sewage sludge incineration and power generation system and sand filtration systems) that have high environmental performance and meet customer needs. Also promote establishment of a system for receiving orders for DBO projects, which are expected to continue increasing.

Takuma Energy Co., Ltd., a Group company, operates the Power Retail Business, which draws on power generated by municipal solid waste treatment plants and biomass power plants that Takuma has delivered as its principal sources of power.

Contribute to stabilizing customers’ electricity rates and reducing greenhouse gas emissions through the procurement and supply of electricity generated from renewable energy and non-fossil fuels.

Demand is increasing for renewable energy and CO2-free electricity for decarbonization. Demand is also increasing for local production for local consumption of electric power.

Leverage strength in stable power procurement to promote the supply of electric power to areas near power sources and to environmentally conscious customers. We will also promote expansion of our lineup of related services such as supply and demand management services and environmental value transactions to expand our customer base.

We supply construction and maintenance services for biomass power plants and Energy from Waste plants with a focus on Thailand and Taiwan, where we have local subsidiaries.

Contribute to solving issues such as power shortages and sanitation in Southeast Asian countries due to economic growth and urbanization by supplying waste and biomass power plants.

In Thailand, demand for Energy from Waste and for biomass power generation, including fuel conversion, is expected to grow against the backdrop of government promotion of renewable energy. In Taiwan, demand for facility renewal and service life extension is expanding due to the aging of Energy from Waste plants. In Taiwan and Vietnam, the need for in-house processing of industrial waste generated in manufacturing plants is also increasing.

Aim to expand collaboration with local subsidiaries and partnerships with local companies to increase orders in Southeast Asia and Taiwan. In addition to reducing costs and shortening construction periods, the Company aims to differentiate itself in terms of performance and quality, including stable operation and high-efficiency technology, and to achieve stable profitability and growth by continuing to receive at least one to two new construction orders per year.

Group company Nippon Thermoener Co., Ltd., manufactures, sells, and maintains general-purpose boilers in addition to designing and building related heat source equipment and systems for various types of manufacturing plants as well as hotels, hospitals, commercial buildings, and other facilities.

Through various heat source products, addressing the challenges of heat utilization and energy-saving needs across a range of facilities, including manufacturing plants, hotels, hospitals, and commercial facilities.

Domestic market has matured, but we expect a certain level of demand for renewal and other work to continue for the time being. In addition to new heating businesses (hydrogen, biomass, electric heat sources, decarbonized products, etc.), Takuma group aims to expand the scale of orders by expanding its overseas business in Southeast Asia, particularly in Thailand.

IHI Packaged Boiler Co., Ltd. became a consolidated subsidiary of Takuma Co., Ltd. on April 1, 2025. In addition, Nippon Thermoener Co., Ltd. and IHI Packaged Boiler Co., Ltd. are scheduled to merge on April 1, 2026. By combining the product lineups and technological capabilities of both companies, which have high shares in the domestic general-purpose boiler market, Takuma group will establish a supply system for products and services with higher added value.

Group companies Sunplant Co., Ltd., and Dan-Takuma Co., Ltd. design and build various types of building equipment, including air conditioning, water supply and drainage sanitation, and firefighting systems, and they manufacture, sell, and maintain equipment for the semiconductor and electronic device industries, including clean rooms, chemical air filters, and magnetically shielded chambers.

In the Building equipment business, strong demand is expected to continue due to urban redevelopment and new construction and renewal of medical and welfare facilities. The Company will continue to further strengthen its sales and construction capabilities by securing and training human resources, thereby maintaining and expanding the scale.

In the Semiconductor industrial equipment business, The semiconductor and electronic device manufacturing equipment market is growing over the medium to long term due to the trend toward digitalization. Aim to maintain and expand the scale by providing products that create and maintain a highly clean environment required for the manufacturing process.