Thanks to continuous washing of the filter material, the filtration exhibits stable performance and is adequate both for advanced treatment of discharged water and for generating fresh water from recycled water.

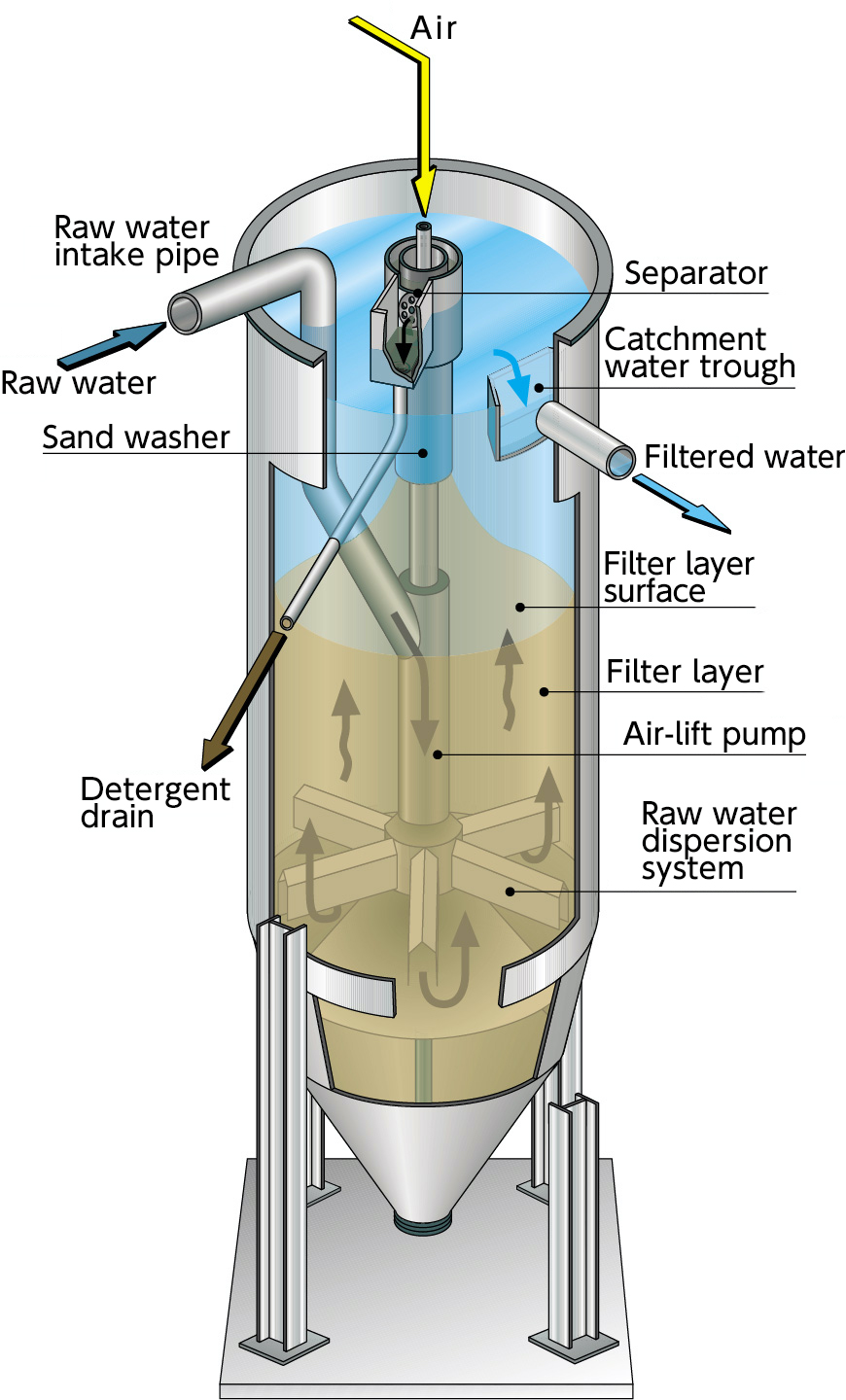

Structure and Principles

Filtration process

Raw water passes through the raw water dispersion system from the raw water intake pipe and moves up through the filter layer. Suspended solids in the raw water are captured by the sand layer as the water moves up through the filter layer, and clear filtered water flows out of the system from the catchment water trough.

Washing process

The filter material is continuously washed as the raw water is filtered.

【Primary washing】

Filter material is sucked up from the bottom of the filter vessel by an air-lift pump. As a mixture of air and water move up inside the air-lift pump, suspended solids are separated out and washed away.

【Secondary washing】

Filter material is separated from the waste water containing suspended solids by the separator at the top of the filter vessel before reversing direction, precipitating inside the sand washer, and returning to the layer surface. When passing through the sand washer, the sand is washed a final time by some of the upward-moving filtered water.

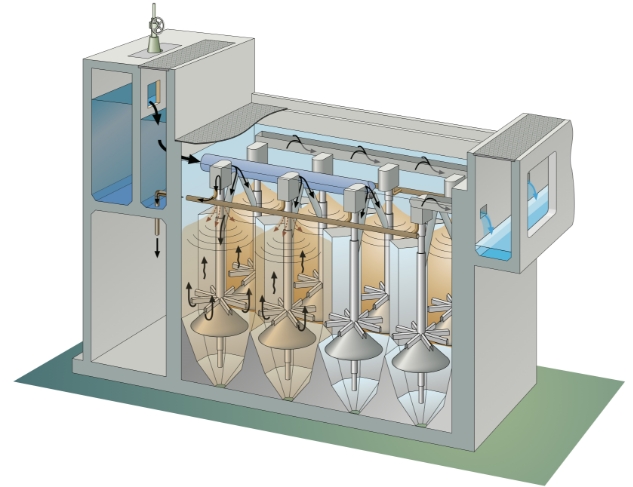

Steel package-type systems for small- and medium-scale installations

Rc basin multi-module type for large-scale installations

Features

Continuous operation made possible by continuous washing

The system delivers stable filtering performance at all times due to contaminated sand being continuously and simultaneously washed as sand filtration progresses. Additionally, there’s no need for intermittent operation to allow for a backwash process.

Applicable to high-speed filtration (filtration speeds of up to 1,000 m/day)

We can accommodate a broad range of filtration speeds, from the 300 m/day standard type to high-speed types that operate at up to 1,000 m/day.

Simple, space-saving design

The system requires significantly less installation area than a conventional fixed-bed filter system as it requires no backwash equipment and can perform high-speed filtration.

Low and uniform loss of filter layer pressure

Low pressure loss maximum at approximately 1 m allows reduction of pumping power. Systems can also be designed under gravity flow.

March 2007: Obtained "The Construction Technology Review and Certification (Sewerage Technology)", Japan Institute of Wastewater Engineering and Technology

March 2013: Obtained "Selected New Technology (Type 3)", Japan Sewage Works Agency

Applicable for various purposes

In addition to removal of suspended solids, the system can be used for denitrification and dephosphorization. Click here for details.

Installations can be updated to moving-bed sand filtration systems utilizing existing civil structures such as fixed-bed filter basins.

Existing equipment can be updated to boost treatment volume by applying a high-speed system.

Past projects

Treated sewage advanced treatment and reuse systems

Water purification and treatment systems

Pond purification and treatment systems

Waste incineration plant wastewater treatment systems

Landfill leachate treatment systems

Agricultural community wastewater treatment systems

Factory wastewater treatment systems

We have an extensive track record that includes the systems listed above.