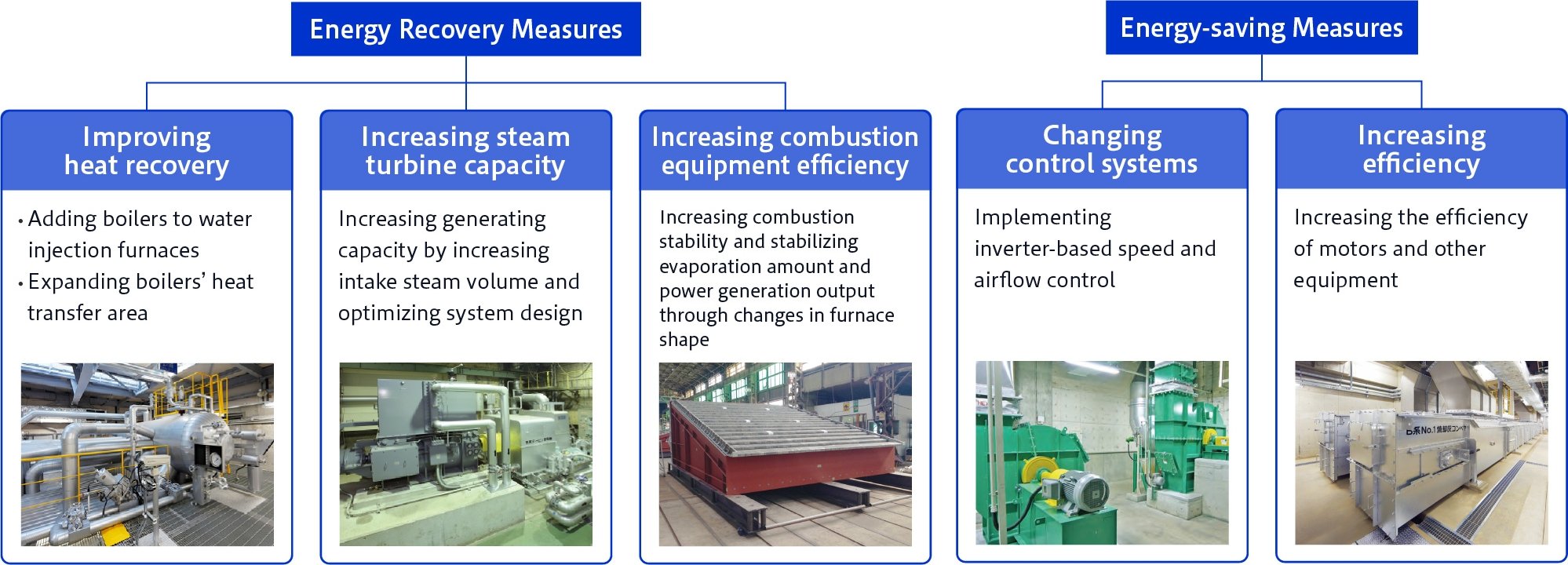

These projects improve performance and extend service life by introducing the latest technologies.

Although municipal solid waste treatment plants are required to operate for many years, the equipment they use needs to be updated once 20 or more years have passed since the start of operation. In addition, legal and social changes sometimes necessitate large-scale modifications.

TAKUMA uses the sophisticated heat utilization and energy-saving technologies it has developed as a boiler and environmental plant manufacturer to carry out large-scale, high-added-value modification projects to help extend facilities’ service lives, reduce CO2 emissions, and lower running costs.

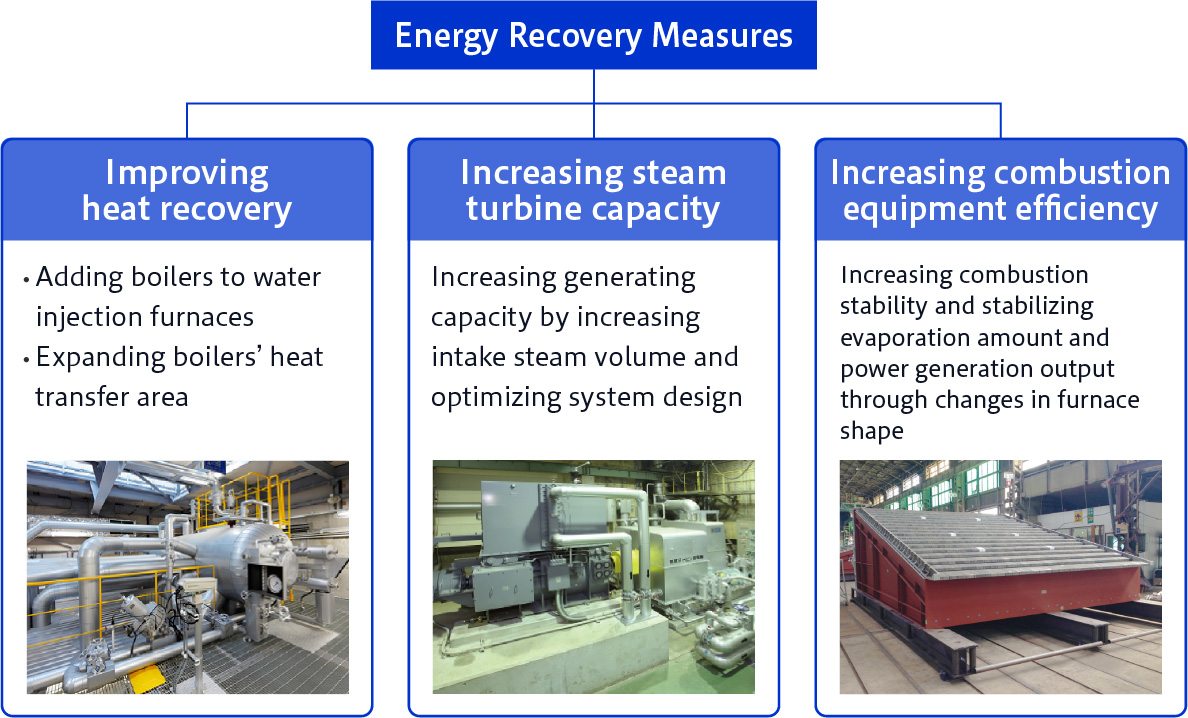

Improving Heat Recovery

Increasing steam turbine capacity

Increasing combustion equipment efficiency

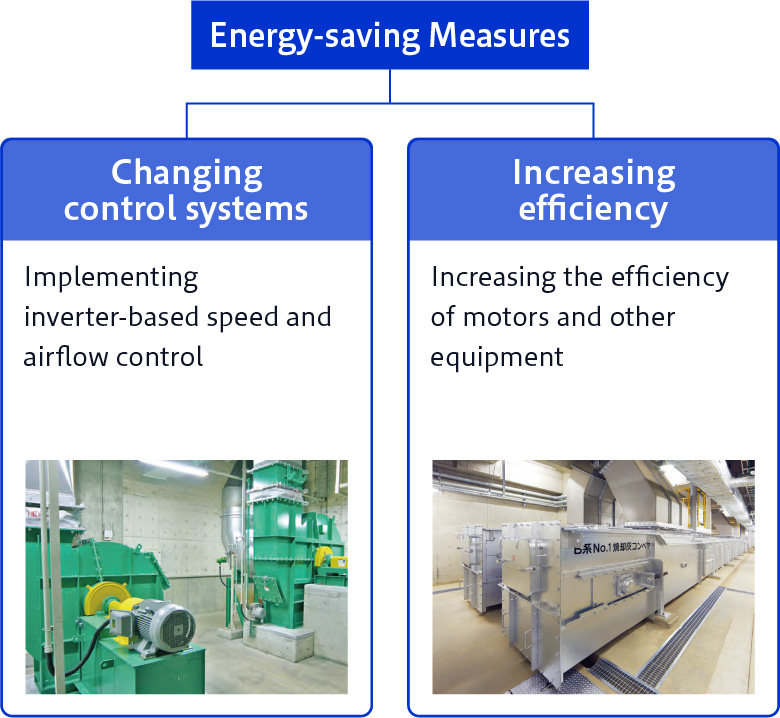

Changing control systems

Increasing efficiency