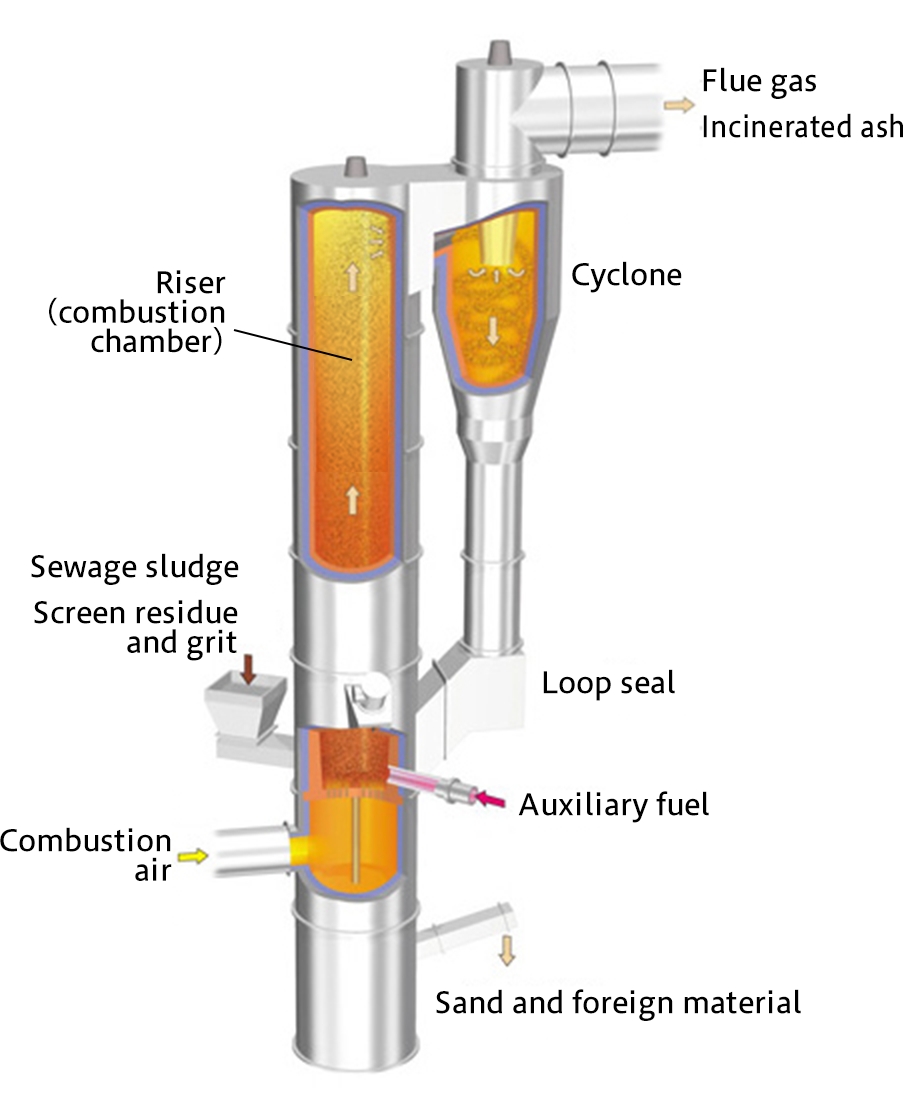

Circulating fluidized bed sludge incinerators pump fluid sand up from underneath the combustion chamber with air so that it is captured by a cyclone and returned to the combustion chamber. Extensive mixing and agitation by the fluid sand occurs throughout the furnace, facilitating extremely fast drying and combustion.

Excellent mixing and agitation performance

Extensive mixing of heat, sludge, and air occurs inside the furnace due to the high gas flow rate to allow complete combustion with a low air ratio of approximately 1.3.

Uniform furnace temperature

Stable combustion inside the furnace ensures sludge burns at uniformly high temperatures (850°C to 900°C). Heated fluid sand circulates and returns to the bottom of the furnace to keep the temperature there stable, reducing the need for auxiliary fuel.

Compact furnace shape

Thanks to a high superficial velocity in the furnace, the furnace diameter is half that of a bubbling fluidized bed furnace.

Reduced fluidizing blower power consumption

The required pressure for the fluidizing blower is low so the power cost is reduced by 30% to 50% compared to a bubbling fluidized bed furnace.

Excellent flue gas properties

Effective agitation and mixing yields low-CO, low-NOx flue gases.

Ideal for mixed combustion

Excellent agitation and mixing makes this design well suited to mixed combustion with foreign substances such as screen residue and grit. It can accommodate screen residue content ratios of 0% to 100%.

Compatible with the full range of sludge properties

TAKUMA’s circulating fluidized bed sludge incinerators can handle a wide range of sludge properties, from sewage sludge and dehydrated cake to dried cake.

After-sales Services